Sliding door selection skills - How to maintain sliding doors?

Sliding door selection skills - How to maintain sliding doors?

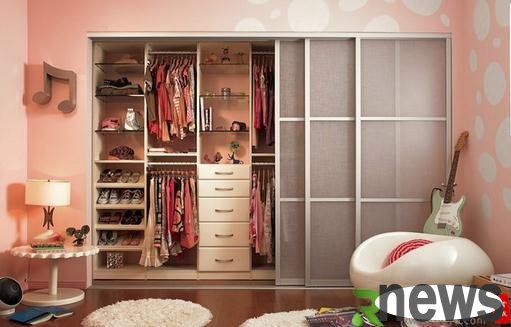

Sliding door selection skills

1, look at the thickness.

If glass or silver mirror is used as the door core, it is generally 5mm thick; if wooden boards are used as the door core, it is best to use 10mm thickness. In order to save material costs, some manufacturers use thinner wooden boards (8mm or even 6mm) instead. The wooden board that is too thin will appear light and shake when pushed and pulled, and has poor stability. Moreover, after using it for a period of time, it is very easy to warp and deform, and the guide rail is stuck, resulting in unsmooth push and pull, affecting normal use.

2. Look at the paint surface.

The paint surface is double-layered before spraying and transfer, that is, surface dust removal and decomposition, which increases the adhesion of the paint surface and the paint surface will never fall off. However, the profiles of some small manufacturers are simply furnished, or even furnished, so the paint surface is easy to fall off and the texture is unclear.

3. Look at the board.

The wooden boards used for sliding doors (mainly fiberboard and particleboard) are all artificial boards, and the adhesives used contain harmful substances such as formaldehyde. Currently, many wall cabinet door manufacturers on the market have mostly produced wooden boards in China, and even use coarse boards. Many of the boards have formaldehyde content that exceeds the standard, which emits indoors and pollutes the environment. In the cold northern season, when doors and windows are closed, it has a greater impact on consumers' physical health.

4. Look at the material of the pulley.

pulleys are the most important hardware components in sliding doors. At present, the pulleys on the market include three types: plastic pulleys, metal pulleys and fiberglass pulleys. Metal pulleys are strong, but they are prone to noise when in contact with the track. Carbon fiberglass pulleys, containing roller bearings, smooth push and pull, wear-resistant and durable, and the box-type enclosed structure is effective in dustproof, which is more suitable for northern areas with heavy wind and sand. The two anti-hopping devices ensure safety and reliability during sliding. The wheels of some low-end sliding doors are made of organic plastic and are very easy to wear and deform. They will rise and fall after a long time of pushing and pulling. The open wheel structure is easy to get dust and wear the internal bearings, making it difficult to ensure flexibility in push and pull. An anti-hop device does not even have an anti-hop device, which is easy to derail during push and pulling, which is very unsafe.

5. Understand the warranty period.

The sliding door manufacturer with poor strength may make a pleasant warranty promise to customers in order to accept orders before sales. When the customer finds problems during use, he or she needs after-sales service, he or she or refuses to hear or deals with them casually, and all kinds of service problems will be exposed.

Cleaning and maintenance of sliding doors

1. The frames of sliding doors are mostly metal materials. You can wipe them with a dry cotton rag during daily cleaning. If you clean with water, try to wring the rag to avoid damage to the metal surface and affecting the appearance.

2. Most sliding door panels are glass or high-density panels. For glass door panels, you can wipe them with a dry rag on weekdays. Every once in a while, use diluted neutral detergent or glass-specific detergent, and then wipe them dry with dry pure cotton or non-wool-free rag; for high-density boards, it is not advisable to wipe them with general detergents, and wipe them with a dry pure cotton rag. If you clean with water, be sure to wipe them with a dry pure cotton rag.

3. The bottom rail is prone to accumulation of floating dust, which directly affects the sliding of the bottom wheel, thereby affecting the service life of the sliding door. Therefore, you should pay attention to using a vacuum cleaner to remove dust from the bottom rail, dip the rag in water to clean the edges and corners, and also pay attention to drying with a pure cotton cloth that does not shed hair.